Gone are the days where the only piece of electronics

you needed was a multi-meter. Even going to Halfords and buying one

of the vehicle diagnostic contraptions won't help the Scorpio owner.

With the development of the PCM (Powertrain Control Module) Ford must have

thought that the days of servicing your own car were over - but as the vehicles

get older and enter 'classic' status the average owner can no longer afford Main

Dealer prices and has to resort to their own efforts to look after their cars.

ENGINE MANAGEMENT

Firstly let me explain a

little about PCMs. The engines of old used to rely upon default

settings for the amount of fuel delivered to the engine, the spark

advance, dwell angle etc Most things were controlled mechanically -

such as the SU carburettor of the A series engine fitted to many

British cars up to the last Minis, which relied upon a tapered needle

rising and falling in a tube (jet) to control the fuel flow and the

Distributor that used weights being spun to control spark advance.

Everything was a compromise and everything went 'out of tune' when

it started to wear.

Not surprising therefore that my first Austin 1300

with twin SUs only managed 28-32mpg whereas a modern 1.4L engine can

achieve 50+ mpg - how do they achieve this?

The answer is the PCM - a

32-bit processor capable of 1.5 million instructions per second. There are lots of sensors mounted around the engine that

detect the flow of air into the engine, the position and rate of

change of the throttle, temperatures of coolant and air etc - in

fact up to 60 sensors on a modern engine, and the PCM measures all of the

values and decides how long to switch on the fuel injectors - longer duration injects more fuel. Finally a sensor in the

exhaust (called the O2 Sensor) detects how much oxygen is left in

the exhaust gas and tells the PCM - this is called a 'Closed

Loop' state and enables the PCM to make allowances for wear and

changes to the engine during it's life - always providing the right

amount of fuel for the situation.

However this is all well and good whilst the sensors

are all working correctly - when one of them fails the PCM gets

confused. Driven by the American anti-pollution legislation,

On Board Diagnostics requires that sensors and actuators controlling pollution

monitoring must be checked regularly and codes generated if there is a fault.

OBDll went one stage

further and required the PCM to actively monitor and test the emissions-related

elements. Since the legislation was due to take effect in 1996 and the 94

Scorpio was one of the first vehicles to have the new EECV powertrain control

module - the Scorpio benefits from the OBDII port, even though the vehicle

doesn't fully comply - there is no MIL (Malfunction Indicator Light), for

example.

Ford therefore included the

full OBDII diagnostics (Diagnostic

Trouble Codes - DTCs) into the PCM to help identify failed sensors

and if you can read the PCM you can see if there have been any

faults recorded - the PCM is clever enough to identify faults that

occur every time you start the engine and faults that only occur

occasionally.

What can you do with the PCM?

Well without

the right tools nothing - it's a sealed box and a simple 16 pin

connector, called the DLC - Data Link Connector. In this case the 'right tools' are a special cable and

connector, a laptop computer and a piece of software. This then

connects to the PCM via the diagnostic connector and reads the

information - it can be used to read and then reset any fault codes

in the PCM and also to read the sensor values that the PCM reads

(Data Logging).

So you can connect up the Laptop and start the

software - with a colleague in the passenger seat you can monitor

say Vehicle Speed, Throttle Position, Spark Advance and Oxygen

sensors as you drive. When you stop you can then replay the data

from your journey and check for values that don't look

right.

I investigated many tools that would do the job but

all were too expensive, ranging from $300 to over $2000. Some only

gave you the DTCs whilst others were designed to change the PCM

program (dangerous without a rolling road!). All of them were only

available from the US - it seems that their freedom of information

Laws help owners get access to all of the data needed from the

Manufacturers. Eventually I tracked down the OBD-2 Scan Tool from

Alex Peper (http://www.obd-2.com/) who claimed to have a low

cost interface that should work with the Ford Scorpio. Taking a

chance I ordered one and a week later it arrived - total cost was

$122 for the unit and another £29 for Customs, VAT and Parcel Force

charges.

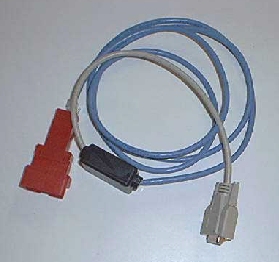

Pictured below is what you receive - it's not as

professional looking as some but for the price it's a bargain and

the software is worth the price on it's own. If you want to order

one then mention it's for the Ford Scorpio and ask for the FORD PWM version

(NOT the ISO one).

Note: Order your leads directly

from Alex at http://www.obd-2.com/ and mention the Ford Scorpio

to obtain the correct version of the lead.

NOTE: The 2.9 12V Scorpio was fitted with the older

EEC-IV PCM and is NOT compatible with OBD2 - See the EEC-IV Code reader

for a suitable fault reader for this vehicle

The black box houses the electronic

circuitry that translates the messages from the car's

computer. The grey cable is a standard PC serial port cable

and the blue cable has an OBD-II connector on the end which connects to the

terminal in your Scorpio. The OBD2 connector is in the coin box to the lower

right of the steering wheel behind a small flap in the roof of the compartment.

No tools are needed to access it.

The black box houses the electronic

circuitry that translates the messages from the car's

computer. The grey cable is a standard PC serial port cable

and the blue cable has an OBD-II connector on the end which connects to the

terminal in your Scorpio. The OBD2 connector is in the coin box to the lower

right of the steering wheel behind a small flap in the roof of the compartment.

No tools are needed to access it.

I used a Pentium 333 MHz laptop with 64 MB of ram but

Alex claims that any laptop (mono or colour) will work or you could

use a desktop PC if the cable reached. The software was designed to

work with 486s and older operating systems like Windows 3.1 (can you

remember that far back?) but is also compatible with 95,98,ME and

2000. Most current computers will run the software with no problems.

I downloaded the VE1-OBD-2 software before the unit

arrived (from http://www.obd-2.com/) as you can access some test

files to get acquainted with the software but the real fun started

when the unit arrived and I sat in the car in the driveway.

You can imagine my disappointment when it failed to connect!

I need to mention that the one area that I feel the

product let's you down is in the Help - don't get me wrong as Alex

will reply to every email within 2 days and is always very helpful,

but the Software's Help files assume that you are very computer and

OBD-2 literate and most of us aren't.

I eventually tracked the problem down to a poor fit

between the OBD-2 connector and the diagnostic port - a push and a

wiggle eventually got the two talking.

USING THE

SOFTWARE

Now, remember that this software was designed for the US spec

Ford vehicles and so we had to expect some 'issues' when using it on the

Scorpio and I'll highlight these as we go through the features.

The software has a very techy feel with computer terms

like "addresses" and "modes" used throughout. You need to

persevere because eventually you get the hang of what you can ignore

and what's important. You need to install the VE1 OBD-2 software

(Alex calls it a browser) from his web site at http://www.obd-2.com/ and also

download the Enhanced Ford data file from the site and place the

file in the same folder as the software. Start the program by

clicking on the OBD2.EXE icon.

INFO Screen

The various screens are accessed from the Tab

buttons and the first screen that comes up is the INFO screen.

The upper text box is for you to enter details of your

vehicle - this is used in the data logger so that when you replay

data you can see which vehicle it refers to. On the right the VIN,

CIN and CVN numbers are collected from the PCM in US Spec cars but

not in the Scorpio - you can enter your own VIN if you wish but I

never bothered as it has no useful purpose.

The Stamp button is for you to enter a description of

a particular time point. So for example you could be driving along

when a misfire starts - shout 'misfire' to your passenger who hits

the STAMP button and enters 'Start of Misfire' as the comment. When

you play the data back you can identify the point when the misfire

occurs and analyse the data from the sensors.

The lower window displays the communications between

the software and the car - most of it is computer speak and as long

as the unit is connected OK then it can be ignored.

Status Screen

This screen tells us the status of all the OBD-II

monitor tests. This is also the screen where you can see if

there are any Diagnostic Trouble Codes (DTCs). In this case, the

Scorpio did not have any codes stored. If it did, we could go

directly to the CODES screen to get the complete listing. There is also a button on this screen which you use to clear any

current codes. The button in this case is not activated since

there are no codes to clear. The MIL light is an indicator used on

US Spec cars to light a dashboard light that says 'Check Engine' -

Scorpios don't have one.

Continuous monitoring refers to all tests that the PCM

undertakes whenever the engine is running - non-continuous tests are

those that only occur after certain conditions have been met -

engine at working temperature etc. You may see NO in these results

if you have only used the car for a short period and the engine has

not yet met the criteria for all of the tests to be run.

Data Screen

This screen is shown populated with data - when you

open it to start with it is empty apart from 3 values - ALL data,

PID possible and $00 PID SUP($01-$20) - I told you it was rather

confusing.

ALL data refers to a REQUEST to the PCM to send all of

the data (names and current values) to the software whilst PID

possible tells the PCM to send the names of all of the data names

only. You have to highlight the value and click SEND to action the

request.

When I hit the $00 PID SUP($01-$20) button however I

received several errors - this is apparently the problem between the

UK spec cars and the US spec software - some of the values are not

supported by the PCM and a dialog window opens to say PID $xx Not

Supported - you can click OK to close the dialog each time but it's

very annoying.

It's far better to use the PID Possible

to see the various options and then select one of the values you

wish to see and then click SEND. A description of the

parameter is displayed at the bottom of the screen and again

requires the operator to have some basic understanding of the Engine

and it's parameters.

To the right of the data screen, you can see a

statistics tab that shows all the important statistical figures for

whatever parameter is highlighted in the list: in this case it is

the load value. There is also an ET tab which allows you to

control the recording of the scan data as if you were using a

stopwatch. You can set start and stop times and even lap

times. A really neat feature. And you can also control

the sampling frequency (how many data points the unit records in a

given amount of time). And lastly, a really clever feature is

the audio checkbox. If you check this box you can keep your

eyes on the road and monitor the parameter of interest as a sound

signal. The frequency of the sound goes up and down according

to the value of the parameter. In this case, if the load value was high I would

hear a high frequency sound.

Graph Screen

This is where the diagnostic power of the software

becomes apparent. You can plot up to three different

parameters at once and compare them to one another to see if they

are responding correctly. In this case, I plotted Load, RPM,

and TPS versus time. If you take the time to go through this,

you can reconstruct the driving conditions very easily.

You could also have multiple parameters graphed together on each of

the three plots. You can also plot one parameter versus another if

you click the circle next to the "z" in the lower right

corner. The limits of your diagnostic power are literally

endless. You can use your imagination to create strategies to

hunt down complicated driveability problems. Note that for the

parameters to become available in the GRAPH screen you must have

selected them in the DATA screen first - otherwise the drop down

choices are empty.

Freeze Screen

This screen is where you can view a freeze frame

snapshot of the data parameters when an emission related trouble

code was set. In this case, there weren't any codes stored so

the screen is empty and I don't know if this feature is enabled on

UK spec cars. It is designed to tell the operator of the parameters

of the engine at the point at which the fault condition occurred.

Codes Screen

This screen is where you can request and list out any

codes that are stored or pending. As mentioned previously in

the STATUS screen section, this is where you would go if any codes

were indicated. You can also press the history buttons to see

what codes have been present and when they were cleared etc. This may help give you an idea of what problems existed in the

vehicle's recent past.

O2 Sensor Screen

This screen is where you could monitor the O2 sensor

output. However this feature is NOT SUPPORTED on the Scorpio.

If you want to monitor O2 sensors then you can request them to be

monitored in the DATA screen and plotted in the GRAPH screen

but this O2 Screen cannot be used.

Test Screen

This screen is where the output for tests that are not

conducted continuously are displayed. The tests that are

available depend on the particular manufacturer and again the three

options of ALL data, TID Possible and $00 SUP($01-$20) are provided

- use ALL data to see what is available for the Scorpio.

Search Screen

Do not use this page unless you fully understand the

workings of the PCM - it is designed for raw access to the data

storage area of the PCM

Dash Screen

This is my favourite page. You can actually set

up a virtual dashboard of gauges for whatever parameters you

want. I've chosen VS, RPM, LOAD, ECT, SFT1, and LFT1 but you

can choose whatever you want to look at. You can even change

the gauges appearance and min, max, and redline values. This

is an appealing alternative to the graph screen when you are

comparing sensor values. Wouldn't it be cool to build a display into

the car that allowed you to select whichever virtual graph you

wanted - in fact the Nissan Skyline GTR has exactly that feature.

Enhanced Screen

By selecting the Enhanced Menu option and using the

Possible command you can review all of the Ford specific data vales

that are available - these were designed for US Spec Fords so don't

be surprised if you get a Mode $22 Not Supported error in a dialogue

when you choose any particular parameter. It simply means that the

PCM did not respond to the request. Also you may see a * appear in

the Data box rather than a value - that means that the PCM responded

to the request but returned no value - again it was not supported in

the Scorpio.

Scanning

When you connect up the laptop and run the software

for the first time you will need to hit the connect menu button. As

soon as you are connected the system starts recording - as you add

each sensor in the DATA screen the data is added to the recording at

the time point that you started measuring it. When you disconnect

the software asks you to choose a filename to store the data in. You

choose a memorable name and it records all of the data which you can

then access by using the REPLAY menu item. If you selected an

Enhanced data then you need to open up the Enhanced page to see the

results - NOTE that enhanced data is not available for use in the

Graph screen. (If you wish you can use the Export feature in the

File menu to save the Data file as a CSV file and import it into

Excel to graph the data yourself).

The real benefit is that you don't have to do your

diagnostics while you're under the bonnet or in the driver's

seat. You can simply record everything of interest and store

it. Then go sit down with a clear head and meticulously go

over what you've recorded to find the problem using the graph screen

and dashboard to see what happened.

Fault Finding

There are a couple of faults

that I came across with the software.

1. Failed to

connect

This was due to a poor connection between the cable and

the diagnostic connector - set the laptop to continuously try and

connect and wiggle the connector - it should connect OK. If not then

make sure that your ignition is on and that the software connects to

the Port of the laptop by checking the messages in the INFO screen.

2. Dialog window displayed saying Mode #xx Not

Supported - caused when the PCM did not respond to a request. If you

select ALL data then the software cycles through each data request

and if the PCM did not respond the dialog window is displayed which

is very annoying. Select individual parameters instead of 'ALL'

(find them first using the PID Possible command) and make a note of any that

cause this problem and don't use them in future. It is

possible to configure the software to be monitoring the values that

you are interested in and then set a Favorite - then when you return

to the software in future and open the Favorites it presets the

data requests to those that you saved previously.

3. Data Underrun or lost data values

The PCM

connector accesses the PCM and it's sensors over a 'BUS' which is

also carrying the sensor values to the PCM - it can get a bit

congested if you are requesting lots of data values and you will

notice the refresh rate for any one data value drop (it can normally

achieve about 4 requests per second for a single value) and also it

will drop data values with an error in the log file saying Data

Underrun or Data Len errors. Unless these cause a real problem over

a long period of time then don't worry - you can try setting the

timeouts to be 3 and the Ford PWM box to be 200 in the

Options/Gateway menu item and that can be beneficial.

4. Software crashes

Has happened occasionally that

the software gets confused and faults although it still seems to

record the data ok. If it happens to you then record what was

happening and email Alex Peper with the details.

Plusses and Minuses

For those of you who want a quick scorecard, I'd have

to summarize it like this:

Plusses

Compact size and portability

Ability to easily

read and clear codes

Datastream access including graphing and

dashboard style gauges

Free future software

upgrades

Data Logging (By far the most valuable

feature)

Low Cost

Excellent software package

Minuses

Needs a Laptop with a serial port

Quite a

technical product

Can be a little buggy

Overall the tool is worthwhile for anyone who feels

competent to diagnose their own problems rather than resort to the

Ford Dealer. I had problems with my EGR system and even Ford could

not diagnose it with their WDS but my laptop eventually tracked it

down to a leaking EGR pipe that was weakening the mixture.

For detailed analysis of trouble codes

and sample scans go to OBD Menu

![]()