|

|

|

| Vehicle |

Ultima 16V 2.0 & 2.3 Saloon |

| Year |

All |

| Mileage |

Any |

| Repair Cost |

£90 + fitting |

| Repair Part(s) |

Ignition Wiring Loom |

In the case of the DOHC engines, both the 2 Litre

16V and the 2.3 16V use a wiring loom connecting the engine sensors and the two

ignition modules which fire the spark plugs. The loom snakes about around the

front of the cylinder head and across the inlet manifold and part of it enters

the cylinder head cover.

Experience has shown that the insulation on these wires is vulnerable to

cracking. This can allow signal loss or induction, and even shorting, and this

leads to misfire, hesitation on acceleration, and poor or unstable idle.

The picture below shows the damaged loom from Pete C's 2L 16V. It had been

temporarily repaired with insulation tape by a local garage mechanic who had

spotted it during an MOT inspection.

The condition of the insulation can clearly be seen on this shot from Pete C.

Deep cracks and the complete loss of insulation close to this plug. The merest

touch against each other, or to earth on the cylinder head, or a touch of

moisture and you have loss of signal to the spark modules and misfires.

The loom concerned is called the Fuel Cut-off Loom and this should be inspected

carefully, especially beneath the inspection cover on the cylinder head where

the heat appears to cause the wire insulation to crack. If any cracking is found

it would be possible to insulate or replace damaged areas, wire by wire, but realistically

this can only be regarded as a temporary measure.

The loom can be ordered from a Ford Main Dealer, cost about £90, depending on

discounts available. It can be fitted by the owner.

Dell, a 2.3 owner, fitted his own loom and supplied the following pictures.

Although it looks intimidating he states that it fairly easy to fit.

He did it piece by piece, starting at the top of the engine by

disconnecting the coils first and worked his way down to the bottom,

disconnecting the old and connecting the new as he went along. It was daunting

to look at but quite straightforward to carry out.

His only difficulty was connecting the last 2 plugs due to having short arms.

One was a small circular rubber plug with a central connector which had to be

pushed onto a single pin (like a small threaded bolt) around the oil filter area

on the engine block, having short arms made it difficult to push home. The other

was a multi plug near the rear of the engine underneath, the original route went

around a "strut": it plugged in but he didn't seem to have enough slack so just

took it direct. A friend of his with longer arms did it in a jiffy, where Dell

had been struggling for some time.

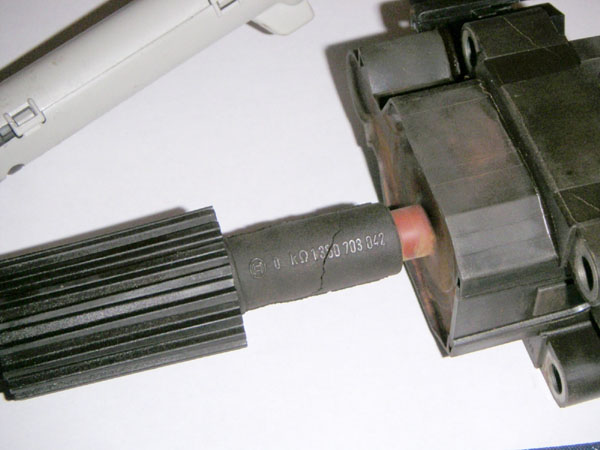

Nodge on the Forum also advises a careful check on the Coil

Packs. He has found damage to the HT extension that passes down to the

spark plug:

Above,

the crack Nodge found on the coil pack can clearly be seen - this caused a

misfire, so be prepared to change the pack if this is found. Thanks to Pete C and Dell for the pix and detail

and to Nodge for the last pic.

EricR

|

| |

|

|

![]()