Changing the Fan (Ancillary Drive) Belt

Mechanical fans are not used in the Scorpio, and instead additional engine

cooling is provided by electric fans mounted on the rear of the radiator. Drive

belts are still required though - for the alternator, water and power steering

pump and the AC compressor where fitted.

For many years Ford used one bolt on the alternator as a fulcrum so that the

alternator could be moved outward to tighten the drive belt and clamped with a

bolt. This had the disadvantage that a new belt could become loose after only a

few miles as it wore in and the alternator needed constant adjustment.

The more modern fitment on the Scorpio is by clamping the alternator to a rigid

mount, and keeping the drive belt taut by means of a tensioner (or two). This

has many advantages - as a new drive belt stretches the tensioner takes up the

slack automatically. The belt cannot be overtightened to cause premature wear on

the alternator or water pump bearings and the shaft bearings of all the

ancillary units are kept at a constant design load. Because the belt cannot

loosen, wear is much reduced - a slipping belt wears 100 times faster than a

gripped one.

The tensioner used by Ford consists of a large clock spring wrapped around one

bolt, engaging in an arm on which a pulley is mounted. Because the action of the

spring is anticlockwise, when engaged the pulley pulls the drive belt at a

pressure set by the spring. As the drive belt lengthens with wear, so the spring

takes up the slack. Because of the constant tension drive belts last for years,

but they should be checked regularly for signs of wear. The belt might become

cracked across its width, normally in the grooved face, or it may become glazed

or frayed in appearance.

There are two petrol installations - one for the DOHC engines which have slight

variations on one drive belt, and the other for the V6 engines, both 12V and

24V. The VM diesel has its own unique tensioner.

NOTE: If the drivebelt tensioner(s) are in good order then they will

swivel about the fulcrum bolt quite easily using only medium force.

However, if the tensioners have corroded in place (after

karchering the engine

bay, for example) then considerable force may be required to release the

tensioner - in this case additional leverage may be required and care used to

avoid injury.

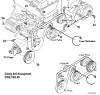

DOHC 8V

The DOHC engine has one drive belt.

In 8V models without air conditioning, the alternator is mounted on the RH side of the block. Where A/C is installed the pump takes its place and

the alternator uses a LH mounting, replacing an idler pulley.

the RH side of the block. Where A/C is installed the pump takes its place and

the alternator uses a LH mounting, replacing an idler pulley.

In both cases the tensioner is as shown. The tensioner pulley is engaged with a

17mm spanner or socket and turned (if necessary with an extension bar)

clockwise. This winds the tensioner further against its spring and provides

enough slack to pull off the drive belt from one of the pulleys - for

convenience the alternator pulley is best. The tensioner can then be gently

released and the drive belt removed from all the pulleys. The new belt is fed

round the pulleys except the last, the tensioner then turned clockwise again,

and the alternator pulley refitted with the drive belt. When the tensioner is

released it will pull the drive belt to its predetermined load. A careful check

to make sure that the belt is properly aligned with all of the pulleys, and the

job is done. 10 minutes, max.

The figures right show the DOHC8V without AC and, lower, with the compressor.

Finis Numbers:

| 8V with A/C |

1 068 252 |

| 8V Less A/C |

731 608 |

DOHC16V

The 16V arrangement is very similar and the drive belt is removed in exactly

the same way. In the case of the 2300 there may be an idler pulley between the crank and the compressor.

idler pulley between the crank and the compressor.

Without an AC pump, the 16V may have an idler pulley mounted instead.

The tensioner and the process is the same.

Finis Numbers:

| 2.0 16V with A/C |

1 068 252 |

|

| 2.0 16V Less A/C |

731 608 |

|

| 2.3 16V Man With A/C |

1 033 499 |

|

| 2.3 16V Man Less A/C |

1 033 500 |

|

| 2.3 16V Auto with A/C |

1 068 252 |

|

| |

|

|

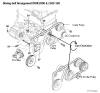

V6 Scorpios 12V & 24V

In the case of the V6 Scorpio there are two drive belts. From the front of the

engine, the AC drive belt is first and has its own tensioner. The picture right

shows this and the tensioner is released in the same way. Once the AC belt is removed, the left hand tensioner

is released and the longer drive belt removed.

released in the same way. Once the AC belt is removed, the left hand tensioner

is released and the longer drive belt removed.

I found that there is enough room to work from the top of the engine with a

short 17mm socket and an extension bar. This provides enough leverage to release

the tensioner without struggling. The tensioner tends to 'lock' in its position

and some effort may be required to make the initial movement.

To prevent damage to the tensioner arm or spring, release the spring pressure

slowly, especially when removing the belt.

Drive belts may be obtainable more cheaply elsewhere than Ford, but IMO quality

might not be the same. I had both belts on my 24V replaced in 1998 and I now see

that they are slightly glazed and might need changing next year - after 60,000

miles!

Finis Numbers:

| 12V Cooling Belt |

6 606 514 |

£13.57 approx |

| 12V A/C Belt |

7 082 866 |

£8.35 approx |

| 24V Cooling Belt |

7 310 607 |

|

| 24V A/C Belt |

7 082 866 |

|

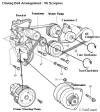

2.5 VM TDI Diesel

The diesel arrangement has changed from that used in the Granada, where the

tensioner was next to the water pump. On the Scorpio the tensioner plate has

been moved lower, next to the crank pulley. Otherwise the procedure is the same.

The tensioner pulley is mounted on a free fulcrum, attached to a tensioner on

its lower edge. This tensioner is then bolted to a plate beneath it which is

held in position by a clamp bolt.

The procedure for removing the driving belt is simply slackening the clamp bolt

shown on the diagram. A 1/2" square drive is placed in the square hole provided

beneath it and the plate is turned fully anticlockwise. This releases the

tensioner and provides enough slack to pull the drive belt away.

With the new belt fitted, the half inch drive is again utilised to turn the

mounting plate clockwise until the tensioner itself measures 82mm between the

bolt centres, then the clamp bolt is tightened to a torque of 65Nm. This

measurement insures that the device is at the correct tension.

The vehicle should then be run for 3 miles or engine run for ten minutes, then

the tensioner length should be checked again.

Finis Numbers:

| VM2.5 with A/C |

1 690 049 |

| VM2.5 less A/C |

1 633 063 |