It's the 19th December,

it's cold and I have 2 T-shirts, a sweater and overalls on and am working

outside on the driveway. With over 1000 miles planned over the Christmas break I

decided that I have to fix my EGR problem.

The problem was that the pipe connecting the exhaust manifold to the EGR

valve had become loose - resulting in an air leak when the EGR valve operated

(on light throttle) and thus a misfire. I had disconnected the EGR mutiplug but

was worried that exhaust temperatures would get too high on a sustained motorway

run.

If you want/need to do this job yourself then prepare yourselves with the

following 'special' tools.

A 1/4" drive socket set with extra long extension bars. I managed to use

3/8" drive but it was difficult.

2 New O'rings for the Inlet Manifold to Throttle housing (Motorcraft Part

Number 1019406 )

Diameter 54.6x2.4

Cost £1.95 each

A new 15mm Olive (Plumbers supplies)

One point to note is that none of the gaskets are available from Ford

individually and need to be purchased as a complete overall kit at

£122 - I declined and reused the old gaskets with no apparent

problems - fortunately they appear to be of a high quality.

NOTE: The Ford

recommended method is that the EGR pipe is replaced every time it is disturbed -

but at £112+vat you may want to at least try this

method!

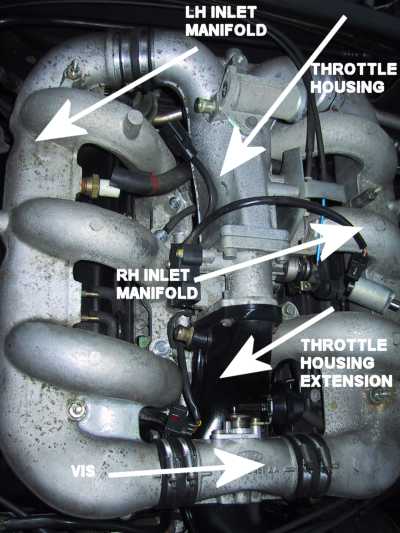

STEP 1

Start by removing the engine cover and disconnecting all of the pipes and

hoses from the left hand inlet manifold. I also found it easier to remove the

air inlet plenum and trunking and the spark plug leads for the right hand

cylinders. Slacken the clips for the VIS and pull it off away from the inlet

manifolds.

Be very careful with the rubber sleeves that hold the VIS and also the left

hand inlet manifold to throttle housing. They are £18 each to

replace!

STEP 2

Slacken the Inlet Manifold bolts in turn - the one that sits under the

throttle body is a real pig - I used a ring spanner and large screwdriver to

lever the spanner until it moved. Removing the plastic throttle housing

extension helps and this is where you will need your 1/4" drive and extensions

to get to the bottom 8mm bolt that holds the plastic housing in place. The Inlet

manifold can now be lifted away and hopefully the gasket is in good condition.

Wipe the gasket gently with Carb Cleaner and place the manifold somewhere safe.

STEP 3

Next disconnect the two throttle cables (easy) and unbolt the throttle body from

the retaining plates (don't drop the bolt into the engine as I did as it's a pig

to retrieve).

The Throttle Housing is now held in place just by the EGR pipe and you need a

10mm socket to undo the pipe at the EGR valve flange. With the Inlet Manifold

removed there is fair amount of room. When loose remove the gasket and bolts -

again the gasket is not available so retain the old one. You can now remove the

Throttle Housing and clean it with carb cleaner.

STEP 4

The EGR valve is removed with its pipe from the Exhaust manifold end and if you

have a friendly Gynecologist then now is the time to employ them. Getting access

to the nuts is a desperate job and will skin your knuckles and cause a temporary

loss of sanity. Eventually with your extra long socket extensions you will work

out how to remove them and when you have retrieved them from where they fell off

under the car you can remove the EGR valve complete with it's pipe.

The offending article - both ends were loose and leaking air and as Ford

decided that they wanted £125 for a replacement I went to my

local plumbers. The joint at the exhaust pipe was just in need of a clean and

polish with emery paper but the other end was where the pipe had flared and the

olive jammed. Attacking this with a blowtorch enabled me to remove the old olive

and polish the pipe with emery. The old olive is stainless steel but I couldn't

find them anywhere so used a 40p brass olive which should outlast the car.

STEP 5

Now the fun part - the relationship between the pipe and EGR valve determines

the position of the throttle body which needs to be aligned with the Inlet

Manifolds - so you need to do some trial fitting (I didn't and so ended up doing

the whole job twice Grrrrr!)

Fit the pipe to the EGR valve loosely and install the unit back onto the exhaust

manifold. Twist the valve so that the flange is vertical - use the throttle body

to align the two flanges and check that the throttle body aligns with the RH

inlet manifold. Then carefully remove the unit and tighten the pipe to EGR valve

joint fully. The pipe should not be able to be moved at this point.

Install the unit and tighten the pipe to exhaust joint

hand tight. Again try a fitment of the throttle body to make sure that you are

in alignment and then fully tighten the flange at the exhaust pipe.

There is a small cylinder that fits between the throttle body and the RH

inlet manifold - it uses 2 O rings to seal the gas and these must be replaced

(they only cost £2 apiece) - If you don't then you will get

an air leak and have to strip it all down again (Grrrrr!).

STEP 6

Coat the O rings with clean engine oil and install the Throttle housing and

reattach the bolts to the throttle cable plates and reattach the throttle

cables. If you have done it right then the flanges at the EGR valve should be in

alignment and you can now refit the gasket and bolt them together. I needed a

small tap with a mallet and piece of wood on the EGR valve to align them and it

didn't appear to do any harm to the sealing of the pipe but be careful.

STEP 7

You can now reinstall the LH Inlet manifold, aligning it with the throttle

housing and with it's rubber sleeve in place. Tighten the bolts not forgetting

the one underneath the throttle housing which needs the ring spanner. Don't

install the VIS yet, tempting though it is to do so.

Reconnect all of the pipes and multiplugs and then the

plastic inlet housing to the throttle body - again the 1/4" extension is needed

as you install the lower bolt first. Now you can install the VIS - place one

rubber sleeve in place on the RH inlet manifold and secure with it's clip. Coat

the inside of both sleeves with clean engine oil and insert the VIS into the

right hand sleeve - don't use a clip just yet. Carefully squeeze the left hand

sleeve through the gap between the VIS and the LH inlet manifold and wriggle it

into position - the oil helps but don't tear it or you are £18 poorer. Finally

secure the remaining 3 clips and tighten.

Reinstall any of the air inlet ducting that you may have removed and the plug

leads and finally the engine cover.

Job done - start the engine and using a piece of plastic

tube listen to each of the joints on the inlet manifolds for any air leaks - you

can dribble a light oil around them and rev the engine, watching for oil smoke

(not steam) if you suspect a leak.

Note: repair did not work as the angle of the pipes

appears critical and has resulted in an air leak - I have therefore disconnected

the EGR system by plugging the vacuum pipe that leads to the EGR valve until I

can try again.