|

|

|

Audible Alert on

Lock and Unlock

The Scorpio comes with two variations of Central Locking. The lower specified

system utilises traditional direct methods. The higher specified system uses

“Global Closing”. This system uses a bus topology to control the locking system

and other features such as power windows, sunroof and seating.

On the Global Closing variation, the locking can be deadlocked by a second

operation of the Key Fob Remote or actuation of the Key Lock; this also arms the

Ultrasonic Interior Alarm Sensors when fitted. After arming in this way, the

system flashes the indicators within a few seconds to acknowledge that the alarm

has adjusted to the cabin and has armed. This may not apply to all vehicles as

this behaviour is modified between markets.

However neither system provides an audible indication that the locks have

operated. The mechanical noise from the locks is low and I found it difficult to

fully be sure the car was locked without actually visually checking, or

deadlocking the car and waiting for the indicators to flash. So it was decided

to add some method of audible feedback.

Possible Methods

With the traditional system, adding a system to detect locking would be

straight forward, however I have the Global Closing system. One option would be

to actually get at a lock motor and break into its feed, however this is

complicated by the fact that this would have to be done inside the door skin, as

the feed to the locks is shared with other modules within the door. More

sophisticated, would be to monitor the bus, decode the signals and initiate a

signal this way. However this was going to be reasonably time consuming, and

would involve interfacing to the bus. I felt that it would be preferable to keep

the system to original specifications.

The third method considered, was monitoring the current flowing to the locking

system, this was the method chosen. The system is passive in its connection to

the locking system and should work on any Scorpio.

Design

It was decided that the system should be easy to fit into the car, i.e. no

major wiring or removal of components. From this the design developed, of a plug

in circuit, which sat in the Main Fuse Box.

|

|

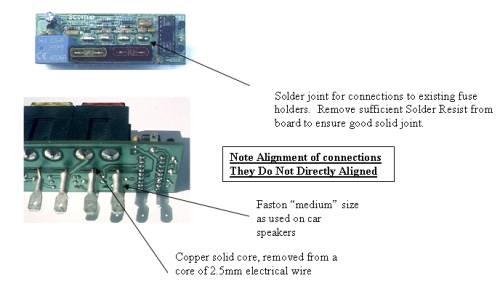

A printed circuit board was designed for the system, this fits into the fuse

box, Fuses 22 and 21 are removed and the board piggybacks into the fuse holders

in the fuse box. Fuse 22 is the locking system fuse and Fuse 21 the heated

mirror fuse.

The operation of the circuit is as follows. When the locking motors are

activated the current flowing through the circuit that Fuse 22 protects

increases considerably, than the level at standby. An isolated Current

Transducer, CT1 is used to measure this current. CT1 provides an analogue output

dependent on load current. This signal is fed to a small microcontroler that has

an internal analogue to digital converter built in. From this the microcontroler

decides if the locking motors are activated. Additionally the way that the

Heated Mirror circuit within the Scorpio is designed, no voltage appears on Fuse

21 the mirror fuse, until the Heated Rear Screen Switch is activated. This gives

a method of signalling the system if required. If the system decides that the

locks have been operated, it produces a 4.5Khz signal that is sent to a piezo

transducer, also an auxiliary output is switched on and off. The auxiliary can

be used to drive an external relay, as to provide indication through the horn or

headlamps if required.

width="100" height="141">

Construction

Some experience with soldering is required to construct this project, that

said it should be reasonably straightforward. The p.c.b. is a double sided

through hole component, with silkscreen and solder resist, this makes assembly

easier. The silk screen shows component identifications, these correspond with

the schematic. It is recommended that the resistors are fitted first, followed

by diodes, capacitors, transistors, resonator, IC socket and voltage regulator.

Lastly the fuse holders and then, the following connector details.

PARTS LIST

| Scorpio Audio Locking Alert |

| Quantity |

Description |

Vendor |

Part No. |

| 1 |

Piezo awd 100dB @ 4.5KHz |

Farnell |

926-991 |

| 1 |

Current Trans LEM |

Farnell |

394-3501 |

| 2 |

Fuse Holders |

Farnell |

581-525 |

| 1 |

PCB Fuse 125mA* |

Farnell |

319-260 |

| 1 |

PIC16C71 |

Farnell |

270-386 eprom/ 270-398 otp |

| 1 |

4mHz Resonator* |

Farnell |

573-589 |

| 1 |

78L05 Vreg |

Farnell |

701-889 |

| 1 |

Transistor PDTC124 (Resistor equipped) |

Farnell |

316-4494 |

| 3 |

All 5% 0.25W Resistor 2K * |

|

|

| 1 |

Resistor 11K* |

|

|

| 1 |

Resistor 22K* |

|

|

| 1 |

Resistor 15K* |

|

|

| 1 |

15V Zenner* |

Farnell |

369-512 |

| 1 |

5.1V Zenner* |

Farnell |

369-408 |

| 3 |

100nF Capacitor* |

Farnell |

750-992 |

| 2 |

22pF Capacitor* |

Farnell |

747-038 |

| 1 |

100uF 6.3V Capacitor* |

Farnell |

301-7527 |

| 4 |

PCB small faston conn for gnd and piezo* |

Farnell |

347-2528 |

| 1 |

18 Pin DIL Socket* |

Farnell |

134-2990 |

I used Farnell

Electronics for the parts. Some components are only sold in multipacks by

Farnell, Maplin Electronics etc can supply some components listed in smaller

quantities but the Current Transducer and Resistor

Equipped Transistors may be difficult to source elsewhere.

Power Connection Manufacture.

Assembly is straight forward, however the most time consuming part is

constructing connections to plug into the existing fuse holders, in the Scorpios

Main Fuse Box.

Large currents can flow in these circuits, so care must be exercised.

The specified PCB mounting fuse holders are rated at a continuous current of

15A, this becomes a possible problem as the door locking circuit is protected by

a 20A fuse. In tests nothing like that current is used by the locking motors. In

extreme conditions, mechanically jamming locks or frozen up locks, these

currents possibly could flow for a brief period. The specified fuse holder will

handle this for some time. If in doubt use a 15A fuse in place of the 20A, if

you have no problems with it blowing.

The connections to the power circuits, i.e. fuse 22 and 21 must be suitably

constructed, as so to handle these currents. The method I chose is shown in the

following pictures. I originally was going to have connections CNC’d and

tin-plated, however time did not allow. I think some one else can come up with a

better method. One list member at least is looking at this.

Use faston spade connectors of the medium general size as used on car radio

speakers, available from Motor World/Halfords etc. They come with a plastic

sleeve, the colour of which identifies the designed cable diameter and current

rating. Use ones with a red sleeve. Strip some 2.5mm electrical wire (twin and

earth) and prepare a striped core, by cleaning it until bright, use a needle

file etc, never wire wool as it contains oils.

The PCB has slits, so designed for a CNC’d assembly, they do not centre with the

fuse holders as they are. Refer to the picture above. Remove sufficient solder

resist from the top of the board around the area to be soldered to. Once you are

sure about the alignment, if necessary open the slits at the required positions

slightly, I used a few turns of a round needle file. Solder in 4 lengths of

about 25mm, you need a soldering iron that can do at least 30W if you want good

results. Ensure the joint is sound, inspect carefully. You do need some

experience with soldering to do this correctly.

Once cooled down place a faston spade, with its outer sleeve in place, over the

wire on the solder side of the board. Very carefully solder the crimp to the

wire, you need to provide the heat for at least 8 seconds until capillary action

draws sufficient solder into the crimp. The crimp needs to be filled with

solder. Carefully, mind your fingers, before the crimp has cooled completely;

use a pair of pliers to pull the still malleable sleeve up and off. Leaving the

sleeve in place until this point, levels the connection at the correct height.

Repeat until all four connections are in place.

The use of copper wire provides some “adjustment” if your alignment is slightly

out.

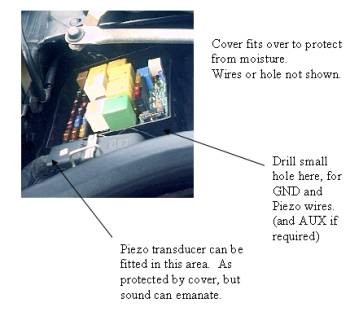

Low Power

The low power connections consist of, GND, outputs to the piezo and AUX.

Thin wire can be used here, the board has provision to mount small faston

connectors for these connections, or solder the wires directly into the board.

The specified transducer can provide considerable noise output. For best results

place a 1K 0.25W resistor in parallel with it, near to its leads.

Software

I used a Microchip PIC16C71, microcontroler. This device comes in two basic

flavours, the one time programmable or otp and the EPROM type. Other devices

could be used including possibly AVR products from Amtel.

The original software is very basic and does not make use of all the possible

features. I used a C compiler for speed and the relevant source code and hex

files are included in awd.zip, so you can program your own

devices if you have access to the facilities.

Click here to download awd.zip

RB1 can be used to detect when rear screen heater is pressed, could use

combination of pushes on this to enter program mode etc. (not done this

yet, in software).

RA0 can be used to monitor battery voltage, this again has not been implemented

in code. But all the hardware is on the board.

Printed Circuit Boards and Programmed PIC16C71

A limited number of pcbs are available, as a reasonable batch had to be

manufactured for minimum quantity reasons. These are available to interested

Scorpio owners.

The PIC16C71 is available ready programmed with the basic original software.

Disclaimer and Legal

No warranties or guaranties are given; no responsibility for damage is

taken, for use of this design. It is provided purely for diy use and you are

responsible for its use and integration. All details, source code etc can be

freely used and modified for non-commercial purposes.

|

|

![]()