|

|

|

INSTALLATION OF 8 SENSOR

PARKING RADAR

This write-up applies to the

Cosworth saloon, facelift model 1998, and an eight sensor parking system for

front and rear bumpers. Although this is specific to the facelift model

fitting it to others will be very similar.

Both sets of sensors (front and back) will pick up objects from approx

1.5 metres away and the unit will start to bleep. The bleep speed

increases as you approach the obstacle until, when

about 0.8 metres away the "attention" light comes

on and at about 0.5 metres away the "stop" light

comes on and the bleeps are fast. The distance display, in tenths of a

metre, also flash and the display indicates which direction you are

going in. (see above) By experimentation I have found that when the display

reaches zero distance, the car is actually about 25 - 30 cm away from

the obstruction, so giving a modest safety margin.

|

1.

1.

Installing rear

sensors

a.

Positioning

sensors

Remove interior panels from the

boot and boot lid, to gain access to wiring for offside light cluster, fuel

cut-off switch, and reversing lights in boot lid. Also remove carpet and

underlay from boot floor.

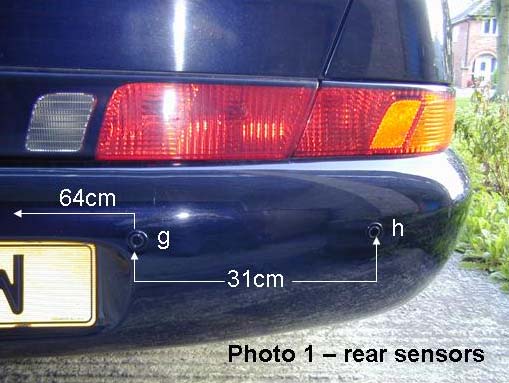

It was not

necessary to remove the bumper. The positions are as shown in Photo 1. I

chose positions that would give a horizontal rearward line for all 4

sensors, but the outer pair were positioned to cover a slightly outward

angled beam.

For the positions shown there were no

obstructions on the inside of the bumper. I used masking tape in the

vicinity of each location before marking the sensor positions. A ⅛th pilot

hole was drilled first, to act as a guide for the hole cutter provided as

part of the kit. When using the hole cutter only minimal pressure was

applied in order to avoid overheating the composite material of the bumper

or running on into any obstruction further behind.

|

|

b. Wiring

Using a length of plastic coated curtain wire, or similar, with each

sensor’s screened cable attached in turn, the cables were fed in the

correct order across the car [In my case, e, f, g, h, going from near to

off side] inside the double skin of the bumper to an oval hole on the

inside at the offside end. Once all wires were through, the sensors were

pressed into the holes until flush with the bumper and the 4 cables

covered with black insulating tape for protection.

|

|

2. Installing front sensors

a. Removal of front bumper

The front bumper must be removed so that positioning the sensors avoids

all strengthening webs, headlamp washers, wiring and other obstructions.

The instructions given on the Ford Scorpio website did not apply to this

car. There are no clips to be rotated 90º on each side and there are

four holding bolts at the front, not two. There is no need to remove the

washer bottle.

The following items secure the front bumper to the car: Remove them in

this order, supporting the bumper at the middle and each side. Removal

is a 2-person operation.

Remove the headlamp side covers, 3 torx headed screws.

Disconnect the cable multiplugs to the front sidelights and indicators

and, if fitted, the fog lights.Remove two plastic screws each side of

the front wings.

|

|

|

Pull off the air intake

pipe extension and remove the four bolts holding the front bumper to the

car – two each side. |

|

| Disconnect the pipe clipped across the rear

of the bumper moulding, which connects the nearside headlamp washer with

the washer bottle. Note the internal web on the bumper |

|

| The sides of the bumper are held to the

front wings by two plastic mouldings (lugs) on each of the wings, which

correspond to slots in the bumper sides. To disengage these care is

required to avoid snapping the lugs. This is done by easing the bumper

sides outwards and upwards slightly.

Once the sides of the bumper are clear of the wings, slide the bumper

forwards away from the car and put it on the ground. I put it on an old

blanket to protect the paintwork |

|

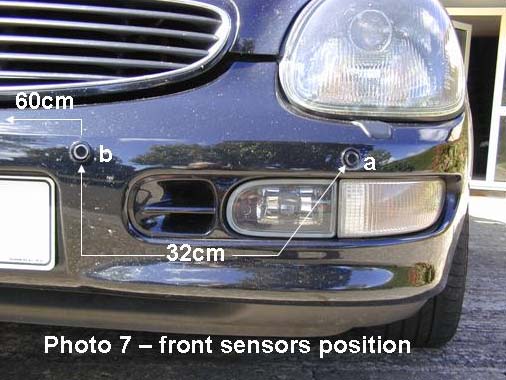

b. Positioning sensors

It is now possible to check that the proposed positions of the sensors

will not foul anything behind the front skin.

Mark up the hole positions as described for the rear bumper, but see

Photo 7 for dimensions, and drill the pilot holes. Use the supplied hole

cutter as described above. |

|

Wiring

Fit the sensors in the correct order across the car [in my case, a, b,

c, d going from near to off side]. I used plastic covered curtain wire

to guide each screened cable inside the double skin to the offside of

the bumper where they exited roughly in the position of the offside

headlight side cover. Once all through, the 4 cables were covered with

black insulating tape for protection over most of their length. The

bumper was then re-attached to the car and secured with the bolts only

at the stage and the loom wiring re-connected.

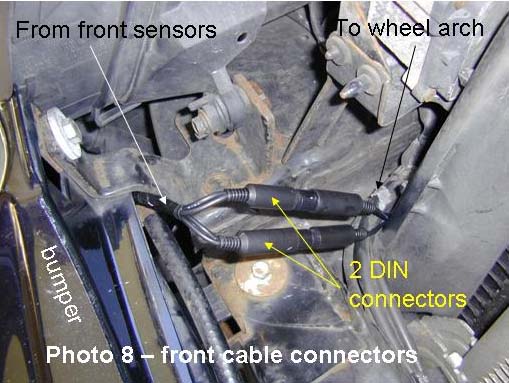

Because the front bumper may have to be removed from the car for other

repair or maintenance reasons in the future, I decided to fit connectors

to the sensor wires. I used two 4-pin mini DIN plugs and sockets, one

for each pair of screened cables (8-pin DIN were not available).

One pair of cables from two sensors was soldered to a plug and the other

pair to a socket, in order to ensure correct re-connecting during any

future operations.

|

|

|

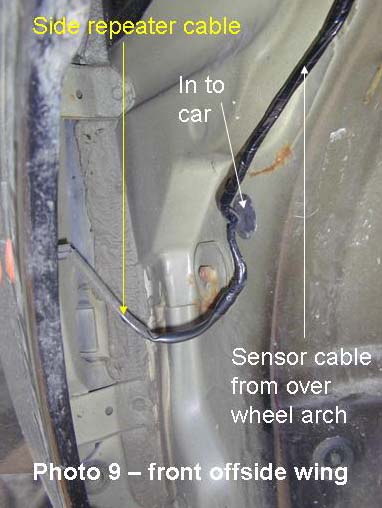

Next step is to remove

the side plastic trim in the driver’s foot well between the door and the

pedals. Then jack up the front of the car and remove the offside road

wheel, in order to remove the wheel arch lining. I then fed the sensor

cables through into the wheel arch via an existing hole above and

forward of the washer bottle filler, over the top of the suspension

[there is a convenient lip or channel to lay the cables in] and down

towards the rear of the wheel arch. I secured the cables with plastic

ties or duct tape where convenient.

There is an existing

cable from the direction repeater light on the wing that goes into the

car interior via a rubber grommet. I fed the sensor cables through the

same grommet and into the car [driver’s foot well].

|

|

| The wheel arch lining

was then replaced and the trailing edge of both sides of the bumper

refastened using new rivets as required. The road wheel was re-fitted

and the car lowered to the ground.

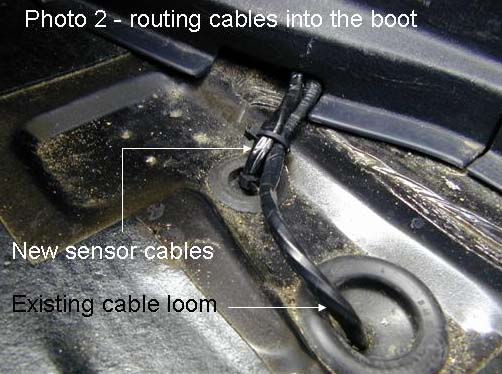

The sensor cables were then routed to the boot under the carpet side

trims, under the rear seat back and in to the boot, clipped to the

existing wiring loom as required all the way back to the rear light

cluster. Plastic trims were replaced afterwards.

|

3. Installing display unit

a. PositioningThe position I chose is shown in Photo 10, as this

enabled me to see through the dipping door mirror and watch the display

at the same time, whilst not interfering with forward vision.

b. Wiring

The single wire from the display unit was concealed between the

dashboard and the door closing trim, down into the passenger foot well

[you will have to remove the trim panel between the door and the foot

well side], and then under the carpet side trim to the rear seat, across

under the rear seat squab and into the boot alongside the front sensor

cables.

|

|

4. Installing the controller

a. Connecting wires to car loom

You now have all the sensor and display unit cables adjacent to the

offside rear light cluster. The Controller requires connecting to an

“ignition on” power supply, negative [I used a bolt on the rear light

cluster] the brake light [this powers the front sensors] and the

reversing light. The cable to the reversing light was led under the rear

parcel shelf and alongside the wiring loom into the boot lid.

I did not cut any existing wires, but pared back the insulation for

about 10mm and soldered the Controller cables to the existing car

cables, insulating the joints afterwards. This will avoid problems with

the sensitive wiring system of this car. To avoid disturbing the loom

and its protective wrapping:-

• the power supply was connected to purple with orange at the fuel

cut-off switch [this is 12v live, but only when the engine is running].

• the brake cable was connected to purple with black near to the rear

light cluster.

• the reverse cable was connected to purple with black near to the

reverse light cluster in the boot lid.

Naturally, it would be advisable on your car to double check the colour

coding and that you have 12v before cutting into any insulation!

|

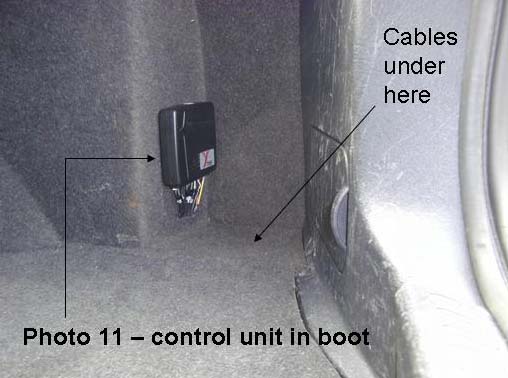

| b. Positioning

The Controller was positioned as shown in Photo 11, and a short slit was

made in the carpet side panel for the cables.

The base of this panel below the Controller is about 20mm above the boot

floor, so is a convenient place for any over length cables to be coiled

up. All that remained was to test the system, to ensure that near side

sensors lit up the near side display and that there were no blind spots

in the sensors’ coverage [there weren’t!], and replace the boot

panelling and floor carpet.

|

|

5. Conclusion

I

am very pleased with the result. The installation looks “original” to the

car and the sensors pick up anything within about 1.8 metres, including high

kerbs. It makes parking in a tight space much easier than before,

particularly as the shape of the Scorpio makes it difficult to judge precise

positioning.

I have

found the unit really excellent. Reverse "sees" further than forward for

some reason and already I have avoided a prang when reversing slowly out of

a blind parking bay and a car shot across my stern from my blind side, but

the sensor went into alarm mode so I instinctively hit the brakes. So, I

would recommend this kit - especially as the Scorpio shape makes it

difficult to precisely judge distances. If front sensors were more sensitive

and if the display was easier to see in daylight, I would award 10 out of

ten. With those two qualifications, I give it 8 out of ten.

Name: 8 Sensor Parking

Radar with Smart

Display

Price: £54.99 + £7.50 p&p and insurance

Seller: gtonline, Belshill UK (email:

tgonline@blueyonder.co.uk)

Neil D

Wallace; August 2004

|

|

![]()